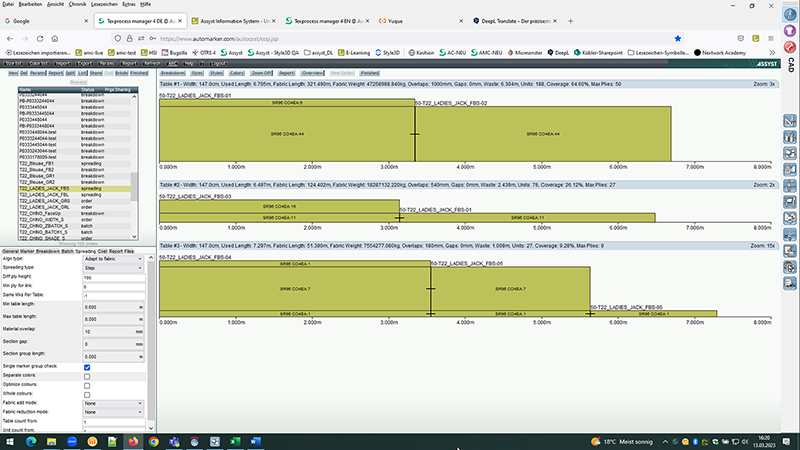

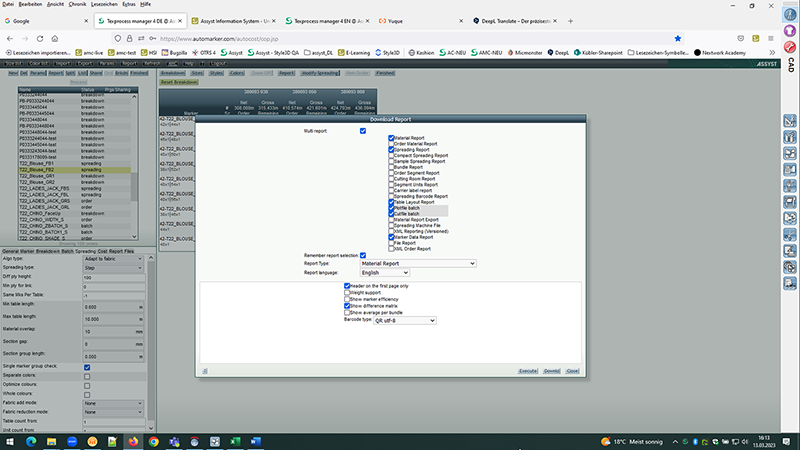

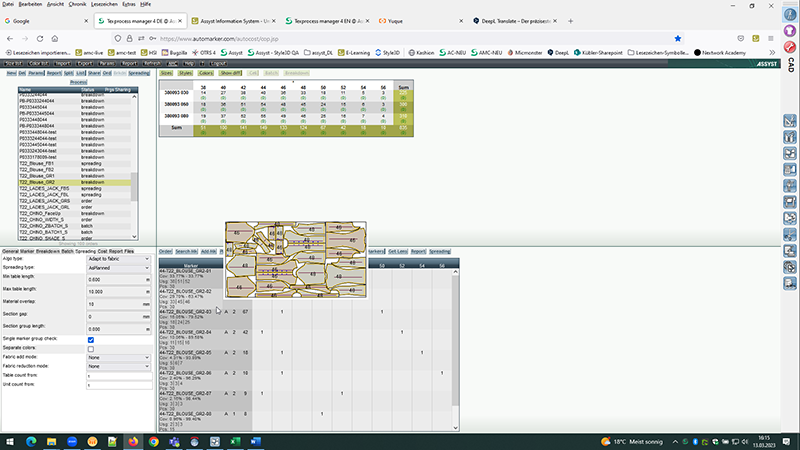

With shell fabric and trimmings (lining, interlining) making up to 60 % of the entire production cost, saving on fabric directly impacts your profit. Autocost is here to help you save. With Assyst’s cut order planning software, you can confidently save on fabric while ensuring quality results and benefit from cost transparency in your entire order process from planning to production floor.